PRODUCT FEATURES

Rubber Wheels Pallet Jack Manufacturer To Rocket Your Business

PRODUCTS

Proud to Offer a Wide Variety of Forklifts

If you are looking for something specific that isn’t listed on our website yet, just contact us today.

ABOUT US

Who is uforklift.com

uforklift.com have seen that today there are also many forklift companies in China & internationally. However, their solutions were still stuck a few years ago.

In fact, we have been upgraded in recent years, and uforklift.com hope our smart and flexible solutions can inject fresh blood into this market.

PARTNER

Who Trust Us

BUYER’S GUIDE

Pallet Jack With Rubber Wheels: How To Make Your Warehouse Operations More Efficient

Are you looking for a way to make your warehouse operations more efficient? As a business owner, you know that having the right equipment can make a big difference in your productivity and operations, but how do you know what is the best type of equipment for your needs?

Pallet jacks with rubber wheels are a good choice for businesses that operate in tight spaces or need to move goods over rough surfaces. Rubber wheels provide better traction than other wheel types and can handle small bumps and vibrations without damage.

In this blog post, we will discuss everything you need to know about this equipment and how it can make your warehouse operations more efficient. Keep reading to learn more!

Table of contents

1. Pallet Jack with Rubber Wheels Definition and Its Purpose

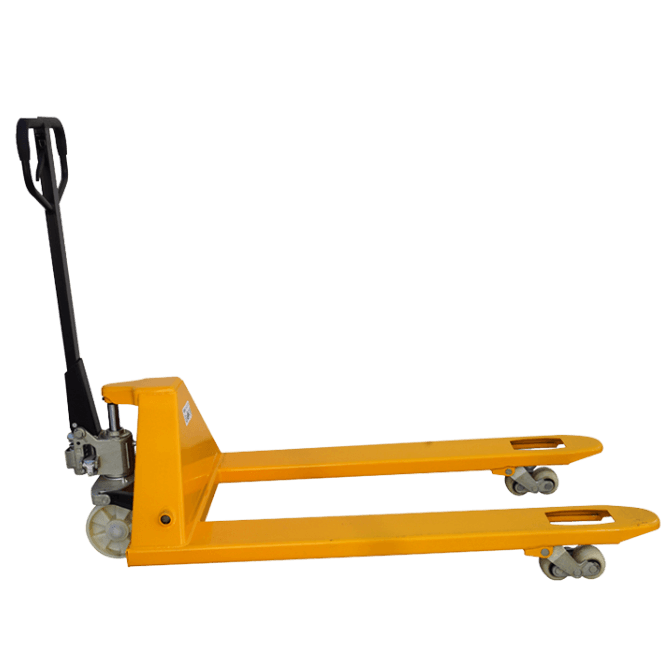

A pallet jack with rubber wheels is a piece of material handling equipment that is used to move pallets or heavy crates from one place to another.

The pallet jack consists of a platform with 4 casters, 2 in the front and 2 in the rear, and a hydraulic lifting mechanism. The load wheels are made of rubber so they can grip the floor and not slip. This specific type of pallet jack is less expensive than those with polyurethane wheels.

2. Effects of Pallet Jack with Rubber Wheels on Warehouse Operations Efficiency

Here are some positive effects of having a pallet jack with rubber wheels on your operations:

Decreases the Risks of Injuries and Accidents

Pallet jack with rubber wheels can decrease the risks of injuries while operating pallets in the warehouse. This type of pallet jack is designed to be more durable and can handle heavy loads. The rubber wheels grip the floor better, which makes it easier to maneuver around the warehouse.

Reduces Noise Levels

Another benefit of pallet jacks with rubber wheels is that they can reduce noise levels in the warehouse. This is important because it can help to create a safer and more productive work environment. Rubber wheels are known for being much quieter than other types of pallet jacks.

Increases Productivity

Pallet jacks with rubber wheels can also increase productivity in the warehouse. This is because they are easier to use and require less maintenance. They are also less likely to break down, which means that there will be less downtime in the warehouse.

If you are looking to improve the efficiency of your warehouse operations, consider using pallet jacks with rubber wheels. Contact us today at Uforklift to check out our latest models!

3. Benefits of Investing in a pallet truck with rubber wheels

If you are looking for a pallet truck that can provide your business with several benefits, investing in a pallet truck with rubber wheels is a smart choice. Here are just 3 of the many benefits that you can enjoy when you make your purchase:

Improved Maneuverability

One of the biggest benefits of investing in a pallet truck with rubber wheels is improved maneuverability. With rubber tires, you won’t have to worry about getting stuck on rough floors or having difficulty making turns. This can save you time and frustration, and it can also help improve your productivity.

Better Traction

Another benefit of investing in a pallet truck with rubber wheels is better traction. This means that you won’t have to worry about your pallet truck slipping or skidding, even on wet or rough surfaces. This can help keep your employees safe and can also help you avoid accidents.

Longer Lifespan

When you invest in a pallet truck with rubber wheels, you can expect it to last longer than a pallet truck with plastic or metal wheels. This is because rubber is a more durable material that can withstand the wear and tear of everyday use.

As a result, you won’t have to replace your pallet truck as often, which can save you money in the long run. Investing in a pallet truck with rubber wheels is a great way to ensure that your goods are transported safely and securely.

4. Raw Materials Used in Pallet Jack with Rubber Wheels

There are a few raw materials that are used in rubber wheel pallet jacks. These include rubber, steel, and aluminum. Each of these materials has the benefits that make it ideal for use in pallet jacks.

Rubber

A great material to use in pallet jacks because it provides a lot of traction. This is important because it helps to keep the pallet jack from slipping when it is being used. Rubber also has a lot of shock absorption, which helps to protect the items that are being transported on the pallet jack.

Steel

Steel is very strong and durable, which means that it can withstand a lot of wear and tear. Steel is also very resistant to rust, which is important because pallet jacks are often used in outdoor environments.

Aluminum

Aluminum is very lightweight, which makes it easy to maneuver. Aluminum is also very corrosion resistant, which means that it won’t rust even if it gets wet.

When you are choosing a pallet jack, be sure to consider the type of material that it is made from so that you can choose the one that will best meet your needs.

5. Manufacturing Process of Pallet Jack with Rubber Wheels

The rubber wheel pallet jack is made up of 2 parts: the frame and the lifting mechanism. The frame is usually made from steel or aluminum, while the lifting mechanism is made from either hydraulic or pneumatic cylinders.

To make a pallet jack with rubber wheels, here’s the process:

Step #1 Raw Materials Shaping

The raw materials are cut into the proper shape and size. This is done by a machine called a shear. The various components are placed on a conveyor belt and moved to the next station.

Step #2 Frame and Lifting Mechanism Are Welded Together

Then, the frame and lifting mechanism are welded together. This is done by a machine called a welder.

Step #3 Painting

After the frame and lifting mechanism are welded together, they are then being painted. This is done by a machine called a paint sprayer.

Step #4 Final Assembly

Finally, the different parts of the pallet jack are assembled into the final product. This is done by workers who use hand tools to put the pallet jacks together.

The completed pallet jacks are then moved to the shipping area where they will be sent out to customers. The whole process usually takes a few days to complete and results in an excellent quality pallet jack that will last for years.

6. Average Cost of a Pallet Jack with Rubber Wheels

As the pallet jack is a vital part of any business that deals with shipping and receiving, it is important to know how much it will cost to purchase one. The average cost of a pallet jack with rubber wheels is around $300.

This price can vary depending on the brand, model, and features that you need. You can find pallet jacks with rubber wheels for as little as $200 or as high as $400. Pneumatic pallet trucks usually cost around $100 to $200 while soft wheel pallet trucks are usually priced around $200 to $300.

The average cost of this equipment is a reasonable price for such an important piece of equipment. Be sure to do your research and find the model that best suits the needs of your business.

Otherwise, you can contact us at Uforklift and we would be more than happy to help you find the perfect pallet jack for you for an affordable price.

7. Where To Find Pallet Jack with Rubber Wheels

When looking to buy a pallet jack with rubber wheels, the best place to start is by contacting Uforklift. We offer a wide range of pallet jacks with rubber wheels that are built to last and can handle even the most strenuous jobs.

Uforklift has one of the best models of forklifts available on the market. The team of experts at Uforklift will help you choose the right equipment depending on your budget and warehouse needs.

8. 6 Buying Tips and Traps to Avoid About Pallet Jack with Rubber Wheels

When it comes to pallet jacks with rubber wheels, there are a few tips for you to follow and traps that you’ll want to avoid. These include:

| No. | Tips |

| 1 | Do Your Research Before You Buy |

| 2 | Don’t Be Afraid to Ask Questions |

| 3 | Be Aware of Hidden Fees |

| 4 | Beware of Unnecessary Upgrades |

| 5 | Get a Warranty |

| 6 | Compare Prices |

#1 Do Your Research Before You Buy

There are a lot of pallet jacks on the market, and not all of them are created equal. You’ll want to make sure that you’re getting a quality product that will last. Do your research and read reviews before you make your purchase.

#2 Don’t Be Afraid to Ask Questions

If you’re not sure about something, ask the salesperson. It’s better to be safe than sorry. There are a lot of different factors to consider. If you don’t know what you’re looking for, you could end up with a subpar product.

#3 Be Aware of Hidden Fees

When you’re shopping for pallet jacks with rubber wheels, it’s important to be aware of hidden fees. Some pallet jack manufacturers will advertise a low price but then hit you with hidden fees that drive up the cost of the product. Make sure you know what you’re paying for before you make your purchase.

#4 Beware of Unnecessary Upgrades

Some pallet jack manufacturers will try to sell you unnecessary upgrades. Don’t be fooled by these scams. Stick to the basics and don’t buy any upgrades that you don’t need. You’ll just be wasting your money.

Some companies will charge extra for things like delivery or assembly. Be sure to ask about these fees upfront so there are no surprises later on.

#5 Get a Warranty

This is always a good idea, especially if you’re spending a lot of money on a pallet jack. That way, if something goes wrong, you’ll be covered. Warranties on industrial equipment usually include pallet truck wheel replacement or repair.

#6 Compare Prices

It’s always a good idea to compare prices before you buy anything. This is especially true when it comes to rubber wheels for pallet jacks. There are a lot of different pallet jack manufacturers out there, and they all have different price points. You’ll want to make sure you’re getting the best deal possible.

By following these tips, you can be sure that you’ll end up with a pallet jack that will serve you well for years to come. Do your research, ask questions, and be aware of hidden fees, and you’ll be just fine or just contact us at Uforklift now!

You want might want to watch this video on how to replace wheels of your pallet jack.

9. Conclusion

To increase warehouse efficiency, it’s important to use the right equipment. Pallet jacks with rubber wheels can make a big difference in how smoothly your operations run.

If you’re looking for a stock of pallet jack that will help you get the most out of your warehouse, contact us at Uforklift. We have a wide selection of pallet jacks and other materials handling equipment that can help improve your operations.

Let us help you find the perfect piece of equipment for your business!